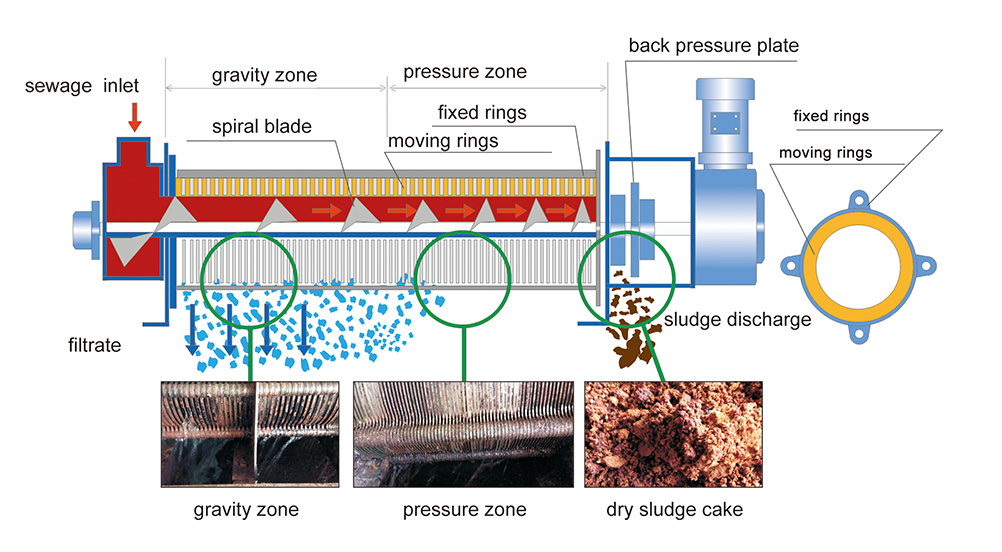

Prinsip Kerja:

Sludge anu dikondisikeun diasupkeun kana zona dewatering tina tank flokulasi. Salaku eta progresses ngaliwatan sela narrowing dibentuk ku aci screw sarta cingcin pindah, tekanan ngawangun nepi na cai laun squeezed kaluar.

Cai dipisahkeun ngalir ngaliwatan sela antara pindah jeung cingcin dibereskeun, nu otomatis cleaned ku gerak cingcin sorangan-éféktif nyegah clogging jeung mastikeun operasi kontinyu. Kue sludge dikomprés tungtungna discharged ti tungtung.

Fitur konci:

Pra-konsentrasi pikeun sludge konsentrasi-rendah

Dilengkepan piring spiral ekslusif, mesin ngalaksanakeun pre-konsentrasi efisien, sahingga utamana cocog pikeun ngubaran sludge-konsentrasi low. Ku ngagentos dehidrator tipe gravitasi tradisional sareng ngahijikeun prosés flokulasi sareng konsentrasi, éta nyederhanakeun perlakuan sludge. The klep kontrol solenoid salajengna ningkatkeun konsentrasi slurry pikeun ningkat kinerja dewatering.

1. Desain Clog-Free sareng Cingcin Ngabersihan Diri

HLDS migunakeun cingcin pindah sarta tetep tinimbang cloths filter, ngaleungitkeun masalah clogging sarta ngurangan kabutuhan pangropéa. Ieu hususna cocog pikeun sludge oily sarta low-konsentrasi, sarta merlukeun euweuh beberesih-tekanan tinggi, ngaminimalkeun polusi sekundér.

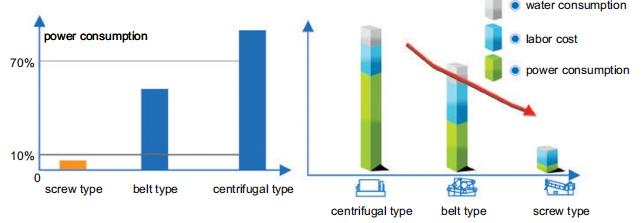

2. Low-Speed, Énergi-Efisien Operasi

Kalayan laju rotasi anu langkung handap tibatan sistem sabuk atanapi séntrifugal, pencét screw HLDS ngirangan pamakean énérgi dugi ka 87,5% dibandingkeun sabuk sabuk sareng 95% dibandingkeun sareng séntrifugal. Ogé ngahasilkeun kirang noise salila operasi.

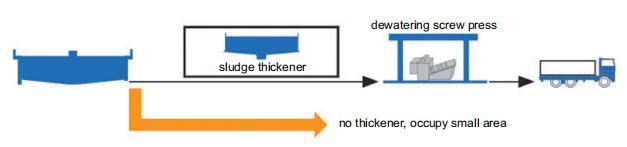

3. Infrastruktur Ngurangan & Biaya Operasi

Mesin dewatering sludge screw bisa ngubaran sludge langsung ti aeration na sedimentasi tanghi, ngaleungitkeun kabutuhan tank thickening sarta ngurangan sékrési fosfor. Merlukeun kirang spasi lantai, ngarah kana investasi modal handap dina fasilitas pengolahan limbah.

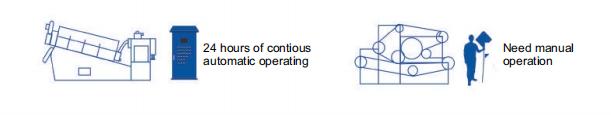

4. Kontrol Otomatis & Operasi Saderhana

Terintegrasi sareng kabinét kontrol listrik berbasis PLC, sistem ngadukung operasi otomatis otomatis. Henteuna komponén rawan bakiak ensures stabil, kinerja low-pangropéa-ideal pikeun fasilitas merlukeun 24/7 operasi unattended.

Aplikasi:

The dewatering screw pencét téh kacida serbaguna sarta lumaku pikeun rupa-rupa jenis sludge jeung industri:

- ✅ Pengolahan air limbah kota

- ✅ Industri pétrokimia & kimia

- ✅ Pabrik pulp & kertas

- ✅ Tutuwuhan farmasi sareng pewarna

- ✅ Pangolahan daging & susu

- ✅ Tambang cai limbah

- ✅ Industri percetakan & lukisan

- ✅ Septic tank sludge

- ✅ Limbah sawit sareng peternakan susu

Naha anjeun ngokolakeun sludge diaktipkeun, sludge DAF, sludge campuran, atanapi sludge anu diendapkeun sacara kimia, mesin dewatering screw press ieu ngajamin efisiensi anu langkung luhur sareng mulang kana investasi.

Parameter Téknis:

| Tipe | Limbah Atah / Runtah Diaktipkeun Sludge / Éndah Kimia | Leyur Air Sludge | Sludge Raw Campuran | ||

| Konsentrasi sludge (TS) | 0,20% | 1,00% | 2,00% | 5,00% | 3,00% |

| HLDS-131 | ~4kg-DS/h(~2.0m³/jam) | ~6kg-DS/h(~0,6m³/h) | ~10kg-DS/h(~0,5m³/h) | ~20kg-DS/jam(~0,4m³/jam) | ~26kg-DS/jam(~0,87m³/jam) |

| HLDS-132 | ~8kg-DS/jam(~4,0m³/jam) | ~12kg-DS/h(~1.2m³/jam) | ~20kg-DS/jam(~1,0m³/jam) | ~40kg-DS/h(~0,5m³/h) | ~52kg-DS/jam(~1,73m³/jam) |

| HLDS-133 | ~12kg-DS/h(~6,0m³/h) | ~18kg-DS/jam(~1,8m³/jam) | ~30kg-DS/h(~1,5m³/h) | ~60kg-DS/h(~1.2m³/h) | ~72kg-DS/jam(~2,61m³/jam) |

| HLDS-201 | ~8kg-DS/h(~4,0m³/h) | ~12kg-DS/h(~1.2m³/jam) | ~20kg-DS/jam(~1,0m³/jam) | ~40kg-DS/h(~0.8m³/h) | ~52kg-DS/jam(~1,73m³/jam) |

| HLDS-202 | ~16kg-DS/h(~8,0m³/h) | ~24kg-DS/jam(~2,4m³/jam) | ~40kg-DS/h(~2.0m³/h) | ~80kg-DS/h(~1,6m³/jam) | ~104kg-DS/jam(~3,47m³/jam) |

| HLDS-203 | ~24kg-DS/h(~12,0m³/h) | ~36kg-DS/h(~3,6m³/h) | ~60kg-DS/h(~3,0m³/h) | ~120kg-DS/h(~2.4m³/jam) | ~156kg-DS/jam(~5,20m³/jam) |

| HLDS-301 | ~20kg-DS/h(~10,0m³/h) | ~30kg-DS/h(~3.0m³/h) | ~50kg-DS/h(~2,5m³/h) | ~100kg-DS/h(~2.0m³/h) | ~130kg-DS/h(~4.33m³/jam) |

| HLDS-302 | ~40kg-DS/h(~20,0m³/h) | ~60kg-DS/h(~6.0m³/h) | ~100kg-DS/h(~5.0m³/jam) | ~200kg-DS/h(~4.0m³/jam) | ~260kg-DS/h(~8.67m³/jam) |

| HLDS-303 | ~60kg-DS/h(~30,0m³/h) | ~90kg-DS/jam(~9,0m³/jam) | ~150kg-DS/h(~7,5m³/h) | ~300kg-DS/h(~6.0m³/jam) | ~390kg-DS/jam(~13,0m³/jam) |

| HLDS-304 | ~80kg-DS/h(~40,0m³/h) | ~120kg-DS/jam(~12,0m³/jam) | ~200kg-DS/h(~10,0m³/jam) | ~400kg-DS/h(~8.0m³/jam) | ~520kg-DS/h(~17,3m³/h) |

| HLDS-351 | ~40kg-DS/h(~20,0m³/h) | ~60kg-DS/h(~6.0m³/h) | ~100kg-DS/h(~5.0m³/jam) | ~200kg-DS/h(~4.0m³/jam) | ~260kg-DS/h(~8.67m³/jam) |

| HLDS-352 | ~80kg-DS/h(~40,0m³/h) | ~120kg-DS/jam(~12,0m³/jam) | ~200kg-DS/h(~10,0m³/jam) | ~400kg-DS/h(~8.0m³/jam) | ~520kg-DS/h(~17,3m³/h) |

| HLDS-353 | ~120kg-DS/h(~60,0m³/h) | ~180kg-DS/h(~18,0m³/jam) | ~300kg-DS/h(~15,0m³/h) | ~600kg-DS/h(~12,0m³/h) | ~780kg-DS/jam(~26,0m³/jam) |

| HLDS-354 | ~160kg-DS/h(~80,0m³/h) | ~240kg-DS/jam(~24,0m³/jam) | ~400kg-DS/jam(~20,0m³/jam) | ~800kg-DS/jam(~16,0m³/jam) | ~1040kg-DS/jam(~34,68m³/jam) |

| HLDS-401 | ~70kg-DS/h(~35,0m³/h) | ~100kg-DS/jam(~10m³/jam) | ~170kg-DS/h(~8,5m³/h) | ~340kg-DS/h(~6,5m³/jam) | ~442kg-DS/jam(~16,0m³/jam) |

| HLDS-402 | ~135kg-DS/h(~67,5m³/h) | ~200kg-DS/h(~20,0m³/jam) | ~340kg-DS/jam(~17,0m³/jam) | ~680kg-DS/h(~13,6m³/h) | ~884kg-DS/jam(~29,5m³/jam) |

| HLDS-403 | ~200kg-DS/h(~100m³/jam) | ~300kg-DS/jam(~30,0m³/jam) | ~510kg-DS/jam(~25,5m³/jam) | ~1020kg-DS/jam(~20,4m³/jam) | ~1326kg-DS/jam(~44,2m³/jam) |

| HLDS-404 | ~266kg-DS/h(~133m³/h) | ~400kg-DS/h(~40,0m³/jam) | ~680kg-DS/h(~34,0m³/jam) | ~1360kg-DS/jam(~27,2m³/jam) | ~1768kg-DS/h(~58,9m³/jam) |

| Tipe | Ngaleupaskeun Jangkungna | Diménsi | Beurat (kg) | Daya (kW) | Cai Ngumbah (L/h) | |||

| L (mm) | W (mm) | H (mm) | Kosong | Ngoperasikeun | ||||

| HLDS-131 | 250 | 1860 | 750 | 1080 | 180 | 300 | 0.2 | 24 |

| HLDS-132 | 250 | 1960 | 870 | 1080 | 250 | 425 | 0.3 | 48 |

| HLDS-133 | 250 | 1960 | 920 | 1080 | 330 | 580 | 0.4 | 72 |

| HLDS-201 | 350 | 2510 | 900 | 1300 | 320 | 470 | 1.1 | 32 |

| HLDS-202 | 350 | 2560 | 1050 | 1300 | 470 | 730 | 1.65 | 64 |

| HLDS-203 | 350 | 2610 | 1285 | 1300 | 650 | 1100 | 2.2 | 96 |

| HLDS-301 | 495 | 3330 | 1005 | 1760 | 850 | 1320 | 1.3 | 40 |

| HLDS-302 | 495 | 3530 | 1290 | 1760 | 1300 | 2130 | 2.05 | 80 |

| HLDS-303 | 495 | 3680 | 1620 | 1760 | 1750 | 2880 | 2.8 | 120 |

| HLDS-304 | 495 | 3830 | 2010 | 1760 | 2300 | 3850 | 3.55 | 160 |

| HLDS-351 | 585 | 4005 | 1100 | 2130 | 1100 | 1900 | 1.3 | 72 |

| HLDS-352 | 585 | 4390 | 1650 | 2130 | 1900 | 3200 | 2.05 | 144 |

| HLDS-353 | 585 | 4520 | 1980 | 2130 | 2550 | 4600 | 2.8 | 216 |

| HLDS-354 | 585 | 4750 | 2715 | 2130 | 3200 | 6100 | 3.55 | 288 |

| HLDS-401 | 759 | 4680 | 1110 | 2100 | 1600 | 3400 | 1.65 | 80 |

| HLDS-402 | 759 | 4960 | 1760 | 2100 | 2450 | 5200 | 2.75 | 160 |

| HLDS-403 | 759 | 5010 | 2585 | 2100 | 3350 | 7050 | 3.85 | 240 |

| HLDS-404 | 759 | 5160 | 3160 | 2100 | 4350 | 9660 | 4.95 | 320 |

-

Agen Deodorizing pikeun Tangki Séptik & Runtah...

-

Éfisién Sludge Dewatering kalawan Lempeng Recessed ...

-

Agén Baktéri Nitrifying pikeun Pangolahan Air Limbah

-

Layar statik pikeun Limbah Padet-Cairan Separ...

-

Baktéri Halotolerant - Bioremed Canggih...

-

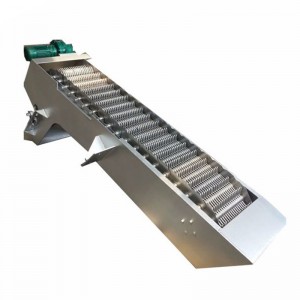

Mékanis Bar Screen pikeun Wastewater Pretreatme...